AUTOMOTIVE

Process of pickling and passivate for AISI 304 Mecamax parts forged as an alternative to the mechanization for automobile injectors.

In the engine field, the use of forged stainless steel has begun to potentiate. Said process generates a lower superficial quality than the mechanization, and therefore the superficial treatments are more critical. In this sense, ESTALKI has worked in the development of a process that uniformly eliminates the superficial ferrite the forge leaves, allowing it to reach 720 hours in the neutral saline fog test.Phosphatic process for Si-Mo cast iron parts used in the gas manifold of the automobile.

The gas manifold of an engine is the zone of the vehicle that suffers most from the effects of corrosion, since in it the corrosive gases concentrate at high temperatures. Commonly, the phosphates have oily films that notably improve the resistance to corrosion. However, said films are not usable in parts that need to be joined to others through welding. In this sense, ESTALKI has developed a system of passivates exempt of oil that give the part the protection required by the manufacturer.Process of decorative chromium plating with high resistance to corrosion.

Despite the fact that decorative chromium plating is a mature technology, ESTALKI has achieved the development of a multilayer system that doubles the resistance to corrosion of the chrome zamak parts in neutral saline fog, even getting to improve the results obtained through the use of duplex or triplex nickel.Treatments of anodization and painting for magnesium.

Magnesium is the lightest structural metal that exists, but at the same time it's the one that more rapidly corrodes; therefore the corrosion protection is an aspect of vital importance. In this sense, ESTALKI has developed several treatments, both inorganic based in the technology denominated plasmaelectrolytic anodized, as well as organic where formulations of high reactivity have been used to achieve an excellent adherence between paint and magnesium.Development of a paint for Audi alternative to the layers of chromic conversion.

Seeing that the current alternatives to the layers of chromic conversion don't match the anti-corrosive properties of these, ESTALKI has developed for Audi a phosphatic primer exempt from chrome with good anti-corrosive properties. Said primer is of easy application and presents a good aesthetic finish, so it can be used as a topcoat in diverse uses.

AERONAUTICS

Process optimization of a chromium-free sealing process for sulfuric acid anodizing treatments as a more environmentally friendly alternative to chromic anodizing (CAA) for unpainted aluminum parts.

Although CAA has been widely used due to its excellent performance, European regulations consider it potentially harmful due to the use of chemicals, which has led to the need to develop a product that complies with the European Union regulation REACH.

BICYCLE

Mate anodization through micro-blast for bicycle reels.

In the high end bicycle sector, aesthetics are closely linked to functionality. Therefore, combinations of shine/matte are sought after in order to enhance the finishes when the bicycle is in movement. That's why ESTALKI has developed an anodized mate that improves the aesthetic of the traditional mate through chemical means.

APPLIANCES

Process of selective enamel for anodized aluminum.

ESTALKI has been able to directly enamel the anodized aluminum through a sophisticated system that joins the use of the latest generation inks with the use of a curing technology unique to Europe. The result of said development is ceramic layers that can be applied in a selective way with a wide fan of decorations and with hardness and resistance to deterioration similar to anodized aluminum.

WIND

Anodization alternative to the chromic for the adhesive union of aluminum with composite materials.

Before the need of eliminating the chromic anodization by the manufacturers of wind turbines as a consequence of the negative effects that the hexavalent chrome has on health, ESTALKI has proposed an alternative based on the sulfuric anodization. Said alternative has been built based on the modification of the work conditions, both of the anodization as well as the posterior sealing. Through this development it has been able to even improve the adherence between the anodized aluminum and the structural adhesives epoxi used in this industry.Development of a paint for metallic components of wind turbines.

The wind industry has witnessed an increase in its anti-corrosive requirements with the irruption of the offshore wind. The wind turbines located at sea present serious corrosion problems, especially in the area affected by the tides. To minimize this problem, ESTALKI has developed a paint that with a lower thickness improves the resistance to corrosion of the formulas it commercializes.

SEVERAL

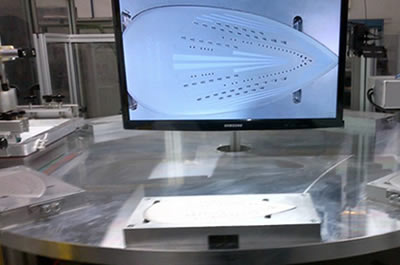

Optimization and industrial development of treatment ALODINE EC2.

In collaboration with the multinational HENKEL, the first European line for the application of the Plasmaelectrolytic Alodine EC2 treatment was installed in ESTALKI. Said treatment presents a high resistance to corrosion, by incorporating titanium dioxide to the traditional layer of alumina of the anodized.