CIDETEC is an applied research organization which integrates three international benchmark technology centers in Energy Storage, Surface Engineering, and Nanomedicine. Since 2003, Estalki Corporation XXI has been part of the CIDETEC Foundation’s Board of Trustees, a technology center with a specialized unit for surface treatments.

www.cidetec.es

CIDETEC is an applied research organization which integrates three international benchmark technology centers in Energy Storage, Surface Engineering, and Nanomedicine. Since 2003, Estalki Corporation XXI has been part of the CIDETEC Foundation’s Board of Trustees, a technology center with a specialized unit for surface treatments.

www.cidetec.es

The Mekatar Group are a group of companies who develop integrated mechanization and surface treatment processes for industrial components of various materials and sizes. The Group combines the productive capacity of the machining companies Mekatar, Mekatech, Mecanizados Guerinda, and Traittech who specialize in surface treatments.

The main activity of these companies is the manufacture of components for the emerging wind industry within the aerospace and aeronautical sectors.

www.mekatargroup.com

The Mekatar Group are a group of companies who develop integrated mechanization and surface treatment processes for industrial components of various materials and sizes. The Group combines the productive capacity of the machining companies Mekatar, Mekatech, Mecanizados Guerinda, and Traittech who specialize in surface treatments.

The main activity of these companies is the manufacture of components for the emerging wind industry within the aerospace and aeronautical sectors.

www.mekatargroup.com

Mekatar focuses on the development of complex machining processes with critical precision requirements for parts as large as 65 tons, and which are comprised of various materials including wrought iron, cast iron, sheet metal, and oxyacetylene sheets. The company primarily works on the component manufacturing processes for the wind, aerospace, and aeronautics industries.

www.mekatar.com

Mekatar focuses on the development of complex machining processes with critical precision requirements for parts as large as 65 tons, and which are comprised of various materials including wrought iron, cast iron, sheet metal, and oxyacetylene sheets. The company primarily works on the component manufacturing processes for the wind, aerospace, and aeronautics industries.

www.mekatar.com

Mekatech was founded in 2014 by the development managers of Mekatar and Mecanizados Guerinda.

The company focuses its activities on machining large parts with critical precision requirements up to 65, which are comprised of tons of various materials including cast iron, wrought iron, and sheet metal, within the component manufacturing processes field of the wind, aeronautics, and aerospace industries.

Quality and reliability assurance in the development of manufacturing processes is also a strategic aspect of Mekatech's activities.

www.mekatech.es

Mekatech was founded in 2014 by the development managers of Mekatar and Mecanizados Guerinda.

The company focuses its activities on machining large parts with critical precision requirements up to 65, which are comprised of tons of various materials including cast iron, wrought iron, and sheet metal, within the component manufacturing processes field of the wind, aeronautics, and aerospace industries.

Quality and reliability assurance in the development of manufacturing processes is also a strategic aspect of Mekatech's activities.

www.mekatech.es

Mecanizados Guerinda focuses on performing machining processes in small and medium parts of up to 2 tons and of various material types, primarily for the customers in the wind and automobile industry.

Quality assurance constitutes an integral part of Mecanizados Guerinda’s activities, which is undertaken using a three-dimensional CNC Mitutoyo machine and a portable three-dimensional machine.

www.guerinda.es

Mecanizados Guerinda focuses on performing machining processes in small and medium parts of up to 2 tons and of various material types, primarily for the customers in the wind and automobile industry.

Quality assurance constitutes an integral part of Mecanizados Guerinda’s activities, which is undertaken using a three-dimensional CNC Mitutoyo machine and a portable three-dimensional machine.

www.guerinda.es

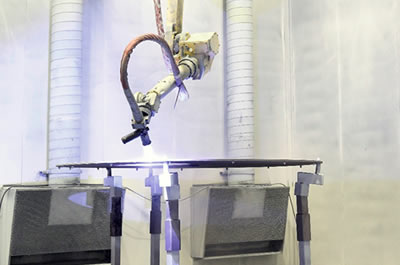

Traittech is dedicated to performing surface treatments using shot blasting, metalizing, and painting the metallic pieces of various materials, particularly those of a large size and in a critical condition of quality.

It uses advanced technology in the application of treatments through the robotization of the shot blasting and metalizing processes.The industrial process is organized through the online realization of parts preparation and the cleaning, shot blasting, metalizing, and painting treatments.

Traittech is dedicated to performing surface treatments using shot blasting, metalizing, and painting the metallic pieces of various materials, particularly those of a large size and in a critical condition of quality.

It uses advanced technology in the application of treatments through the robotization of the shot blasting and metalizing processes.The industrial process is organized through the online realization of parts preparation and the cleaning, shot blasting, metalizing, and painting treatments.

- Pre-cleaning of the parts to be treated.

- Shot blasting: robotization is carried out by means of an auto-directional arm system that incorporates the hoses for shot blasting and 3D programming.

- Metallised: Projection of zinc material by means of an electric arc system launched by an electric-pneumatic equipment onto a shot-blasted surface to ensure optimum corrosion protection.

- Painting: Airless machines with manual application of high density paint. Cabin heating system by means of gas burners with a power of 5.000Kc to ensure the drying processes of the pieces.